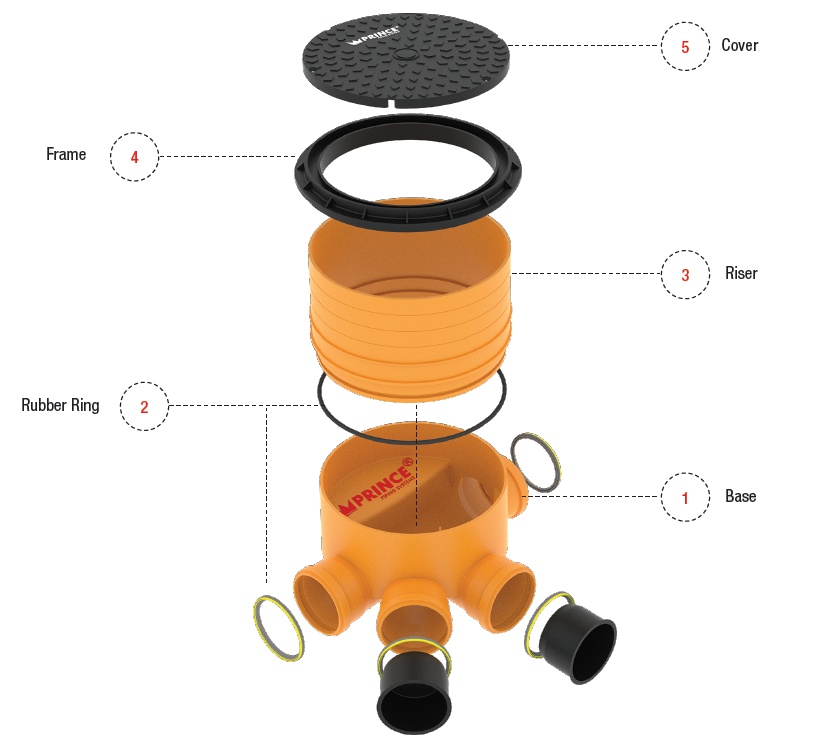

Rapid urbanization means we need to give equal attention to the environmental health. Which means, the underground drainage network needs to be equally efficient for flowing out unwanted sewerage and that it needs regular checking and maintenance. That’s why, Prince Drainfit Inspection Chambers. Made through Injection Moulding Process with the use of Polypropylene material, they have superior chemical resistance over a wide range of bases and acids which ensures good impact strength and low co-efficient of friction. Installed where multiple drainage lines are connected, they allow easy and fast inspection, maintenance and removal of debris which is generated through the flow of sewer waste. DICs are provided in different parts - Inspection Chamber Base, Blanking Plug, Rubber Ring, Riser, Frame and Cover.

Heavy wall thickness and weight enhances durability and load-sustenance.

World class rubber seal provides a leak-proof performance.

Slope provided from inlet to outlet for gravitational flow of sewerage.

Taper provided for preventing waste accumulation inside the chamber.

Corrosion-free stainless steel screws keep the cover and the frame of inspection chamber together and intact.

Blanking plug option is available which facilitates you to keep the outlets open or close as per the requirement.

Drainfit Inspection Chamber comes in different parts (to be assembled properly as per the site requirement)

Straight Through

Left Hand 90° Junction

Right Hand 90° Junction

Left or Right 90° Bend

Left Hand 45° and 90° Junction

Right Hand 45° and 90° Junction