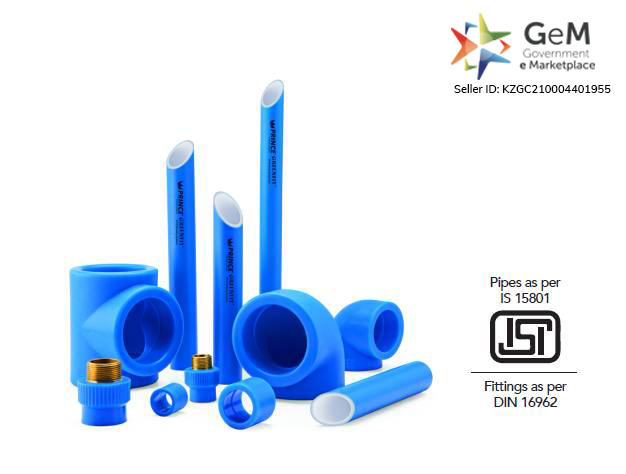

Compressed air, one of the major sources of industrial energy is being used increasingly in manufacturing and process industries. Modern process equipment, pneumatic controls and instruments need clean and uncontaminated air supply for their smooth functioning. In the past few decades, development of more advanced-design compressors and ancillary equipments was heavily felt. So, what we need is a new-age solution for compressed air and vacuum lines. Blue Greenfit industrial piping systems. Made of Polypropylene Random Copolymer (PPRC or commonly known as PP-R material) which can withstand temperatures from -0ºC up to 95ºC. Blue Greenfit is at par with global industry standards and is ideal for pneumatic applications.

Proven hot & cold water performance from -0� C to 95� C

No scaling. Can withstand higher ‘pH’ values

UV resistant triple layered pipes are suitable for outdoor installations that are exposed to direct sunlight

Good chemical resistance - suitable for most industrial liquids

Heat-fusion jointing results in homogenous plastic system ensuring leak-proof joints

Specially formulated thermax pipes reduce linear expansion / contraction of pipes due to temperature variance, ensuring suitability for outdoor application

Compressed Air Lines

Chemical Transport*

Hot and Chilled Water Application

Effluent Treatment Plant (ETP)

Ship Building and Swimming Pools

RO Water Pipeline

Solar Water Heating Systems

Heating System Inside Building Floor, Wall and Radiator Heating

Liquid Food Transportation

Pharmaceuticals and Food Grade Applications

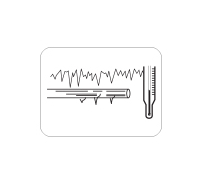

Cut the pipe at a right angle to its axis using burr-free cutter. Ensure that the pipe is free from burrs or cutting chips. Clean the pipe & fitting perfectly before welding. Mark welding depth at the end of pipe.

Do not cut slant/unevenly.

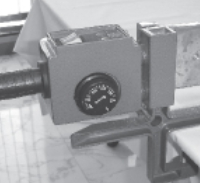

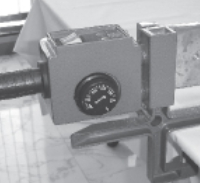

Mount the suitable dyes on the heating element of the welding machine according to the diameter of pipe and fitting. Connect the welding machine to 220 volts A.C. power supply. Select 2600C temperature on the welding machine thermostat. Wait until the required working temperature is reached. Insert the pipe and the fitting in the dyes by exerting light pressure.

Do not proceed with installation of pipe without deburring as the burr when heated will create an extra blockage inside the pipe.

After heating, quickly insert the pipe into the fitting by exerting light pressure. Any misalignment should be corrected immediately after insertion to avoid any stress in the weld. Allow the joint to cool as per the cooling time given in table.

Do not set the temperature of the heater higher or lower than 260°C. Do not initiate the jointing process without gloves. Misalignment of jointing to be corrected immediately before cooling, so as to avoid stress in the weld.

Do not proceed without cleaning as it will create problems during welding due to the presence of dirt or mud.

Although Greenfit PP-R Pipe system material is stabilized for use at elevated temperatures do not expose the pipes & fittings to direct sunlight.

Greenfit PP-R Pipe storage height should not be more than 1.5 meter.

During transportation, Greenfit PP-R pipes should be loaded in a proper manner, otherwise pipes may get deformed.

The Greenfit PP-R Pipe system should be protected from impact of hard and sharp objects.

Before welding/jointing, clean the surface of Greenfit PP-R Pipes & Fittings with a clean piece of cloth and then start welding.

While welding of Greenfit PP-R Pipes and fittings check that the thermostat of welding machine and dyes have reached correct temperature (2600C). While welding, the pipe must not be twisted.

Avoid air droughts during welding to avoid stress in the welds.

Welding machines shall be earthed properly during use.

Do not cool welding machine in water.

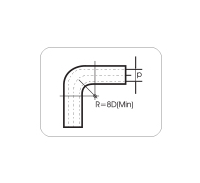

While bending the pipe, the bending radius shall be more than 8 times the diameter of the pipe.

Do not apply direct flame to fabricate bends or crossover pipes, as the direct exposure to fire may cause damage to the Greenfit PP-R pipes. Use only hot air blowing equipment at 1400C. (Cross overs are readily available.)

At sub zero temperatures (00C & below) Greenfit PP-R Pipe system tends to break under impact. Therefore, installation at low temperatures should be done with care, and the pipe lines shall be insulated.

Use 3 layered pipes for outdoor application.